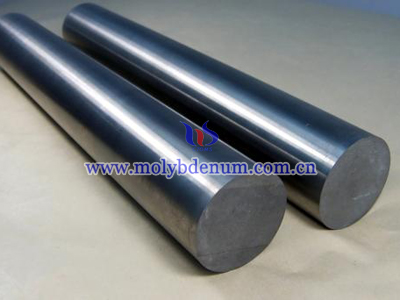

Forged, straightened, and Polished Molybdenum Rods

According to different surface condition of molybdenum rods, molybdenum rods can be divided into three types – forged molybdenum rods, straightened molybdenum rods, and polished molybdenum rods.

| Name | Surface Condition | Surface Color |

| Forged molybdenum rods | No crack, divided layer, burr, but sign with slight hammer mark is admitted. | Surface with oxide is admitted. |

| Straightened molybdenum rods. | No crack, burr, obvious ripple, screw and dimple, but slight notch, furrow, which will not influence usage, are admitted. | The sacrificial color is always black and dark grey. |

| Polished molybdenum rods | No crack, longitudinal vein and rough mark. | Surface with metallic luster and no obvious oxide. |

Forged molybdenum rod

Forged molybdenum rod is also called black molybdenum rod. The surface of it is black brown, but smooth, straight, and no defect such as crack, divided layer, variole, and groove are allowed. They are mainly used for electric boosting glass kiln electrode, blender, electronic components, making different irregular molybdenum products.)

When molybdenum rod has small diameter, it can be rolled into coiling as molybdenum wire. Its surface condition is required lower than black molybdenum rod, but higher than polished molybdenum rod.

Polished molybdenum rod

Polished molybdenum rod, which can also be called cleaned molybdenum rod, must have much higher requirements on its surface condition. Its surface is chemically cleaned to remove all lubricants and oxides it should presents metallic luster and has no oxidized phenomenon notably. What’s more, the surface should have no defects, such as divided layer, crackle, burr and vertical crackle, etc.